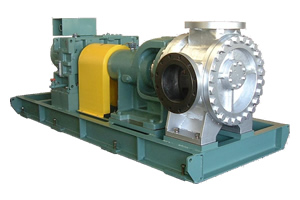

Daido Internal Gear Pump G series has many supply records in liquid transfer of various industries such as petrochemical, pharmaceutical, food etc. We are highly evaluated for its durability and reliability. The gear, which is the heart of the pump, demonstrates a long service life and high efficiency with originally developed Taocloid gear tooth profile.

For our main products G series, there are more than Two Million Selections, combining the main material, material of bush, method of sealing, with or without jacket etc. From among these, we can make an appropriate combination of pump according to customer’s needs.

Performance Criteria

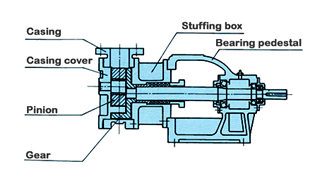

Construction and Theory of Function

-

The gear assembly consists of a gear and a pinion. The gear is mounted on and driven by the shaft, and the pinion fitted with pinion bush and supported on the pinion pin is driven by the gear.

The center of the pinion is eccentric to the center of the gear. A crescent on the casing cover occupies the space between the external circle of the pinion and the internal circle of the gear.

The gear, mounted on the shaft, rotates and drives the pinion. The pinion rotates inside of the crescent and the gear rotates outside of the crescent. The rotation transfers the fluid flooded between the gear and pinion teeth to discharge port. -

- A

- At this point, gear and pinion teeth are in perfect mesh, which acts as a seal between the suction and discharge ports.

- B

- As the gear and pinion teeth begin to discharge, fluid is drawn into and floods the space between the gear and pinion teeth.。

- C

- Fluid flooded between the gear and pinion teeth is displaced to discharge port by rotation.

- D

- As the gear and pinion teeth begin to mesh again, fluid is pressurized and forced out the discharge port.

Main Components

| Name | material |

|---|---|

| Casing, Casing cover | FC250, FCD450, SCS13, SCS14, SCS16, etc. |

| Gear, Pinion | FC250, FCD450, S45C, SACM645, SCS13, SCS14, SUS630, etc. |

| Pinion bush | LBC, Carbon, Ceramic, PTFE, FC200, SiC etc. |

| Shaft | SCM435, SUS304, SUS316, SUS630, etc. |

Example of Application

| Model | N3G-MV | Viscosity (mPa.s) |

20 |

|---|---|---|---|

| Discharge Rate (m3/h) |

1.8 | Fluid Name | Pitch |

| Discharge Pressure (MPaG) |

2.3 |

| Model | N4G-ECM | Viscosity (mPa.s) |

5~5,000 |

|---|---|---|---|

| Discharge Rate (m3/h) |

64.5 | Fluid Name | LP |

| Discharge Pressure (MPaG) |

0.74 |

| Model | N4G-MF | Viscosity (mPa.s) |

15,000~70,000 |

|---|---|---|---|

| Discharge Rate (m3/h) |

6.6 | Fluid Name | Grease |

| Discharge Pressure (MPaG) |

2.0 |

| Model | N7G-M | Viscosity (mPa.s) |

30~5,000 |

|---|---|---|---|

| Discharge Rate (m3/h) |

35~49 | Fluid Name | Synthetic Rubber |

| Discharge Pressure (MPaG) |

0.91 |

| Model | N9G-CM | Viscosity (mPa.s) |

30,000 |

|---|---|---|---|

| Discharge Rate (m3/h) |

60 | Fluid Name | Polymer Solution |

| Discharge Pressure (MPaG) |

1.2 |