-

Internal Gear Pump

High efficiency pump applied with originally developed Taocloid gear tooth (Patented)

-

Seal-less

Seal-less pump combined with Taocloid gear tooth and magnet coupling

-

Rotary Pump

Non-contact pump of trilobal rotor driven via timing gear

-

Vane Pump

Vane pump of simple structure sliding 2 rotor-plates, easy cleaning and disassemble maintenance

-

Vacuum Pump

Reciprocating vacuum pump of solid structure, easy maintenance and high efficiency in the intermediate vacuum range

What is Daido Machinery Corporation

Founded in 1947, we are an independent pump manufacturer that celebrated our 70th anniversary in July 2017. As a “fluid specialist” and “pioneer of internal gear pumps”, we continue to offer “innovation” and “reliability” in various industrial sectors around the world.

As one of the first companies to produce internal gear pumps in Japan, we have developed various improvements and new products over the years, and continued to challenge ourselves as “Daido Machinery Corporation” in sectors such as petrochemistry, pharmaceuticals, food products, and oil to accomplish countless achievements with high-temperature liquid feeding. In addition to the Daido internal gear pumps, we also manufacture and sell reciprocating vacuum pumps, vane pumps, and lobe pumps.

We offer the optimal pumps that match the needs of our customers upon request.

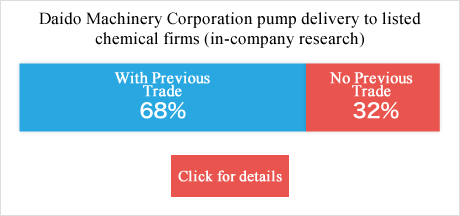

Thanks to our advanced techniques and reliability, our products have been trusted by a majority of domestic listed chemical firms and have received high ratings from our users throughout the world. We have a wide range of achievements especially with high-viscosity and high-temperature liquid feeding.

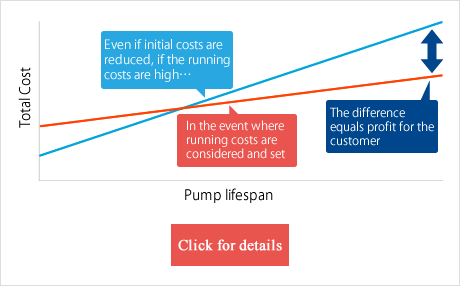

Our internal gear pumps are known for being durable and easy to maintain. The general cost configuration of a rotating machine is said to consist of “15% initial costs, 85% maintenance”. By cutting down the amount of money required for maintenance due to the durability and user-friendliness of our products, we contribute to a total life cost reduction for our users.

We are also concentrating our efforts in expanding overseas. In 2006, we established Daido Hailong Pump(Shanghai) Co., Ltd as a 100% owned local subsidiary in Shanghai, China, and we also have multiple distributors in various countries throughout the world, including our representative office in Thailand. In addition to our affiliate companies, representative offices, and distributors, our business ranges widely throughout Europe (CE Marking), the Middle East, South America, Africa, and Russia.

TOPICS

- About our Contact Form

- News

- We will have annual summer holidays from Aug. 11th, 2019 to Aug. 16th, 2019.

- News

- We will have annual summer holidays from Aug. 11th, 2018 to Aug. 15th, 2018.

- News

- We will have annual summer holidays from Aug. 12th, 2017 to Aug. 16th, 2017.

- News

- July 2nd, 2017 We celebrate company’s 70th Anniversary.

Product Lineup

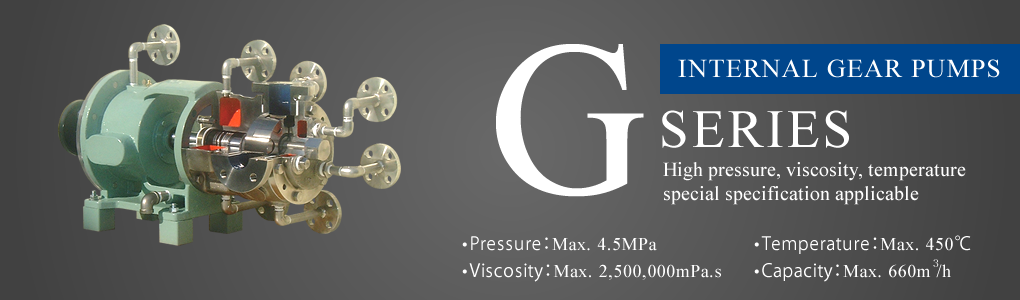

Internal Gear Pumps

-

G Series

- Characteristics

- Japan made, various supply records both in Japan and overseas

- Easy disassemble and cleaning at wetted parts, due to single shaft construction

- Maintenance of wetted part is possible with main body attached to piping

- Excellent durability, made-to-order internal gear pump suitable for special applications

- Wetted part (including shaft seal part) Jacket type is available

- Applied originally developed Taocloid gear tooth profile (patented)

-

SE Series

- Characteristics

- Price is less expensive than G series (SUS)

- Compact design than G series

- Maintenance of wetted part is possible with main body attached to piping

- Applied originally developed Taocloid tooth profile (patented)

- Manufacturing by our subsidiary factory in China, major components are supplied from Japan

-

TG Series

- Characteristics

- Price is less expensive than G series (FC)

- Compact design than G series

- Maintenance of wetted part is possible with main body attached to piping

- Applied originally developed Taocloid gear tooth profile (patented)

- Manufacturing by our subsidiary factory in China, major components are supplied from Japan

Seal-less Pumps

-

M Series

- Characteristics

- Seal-less internal gear pump combined with magnet coupling

- No leakage at shaft seal

- Possible to apply temperature at 200℃

- Applied originally developed Taocloid gear tooth profile (patented)

Lobe Pumps

-

NR series

- Characteristics

- Pump with non-contact originally developed trilobal rotor.

- Liquid is transferred in a smooth manner without being damaged or the solid content being broken.

- Available with both rotation, the suction and discharge line can be freely chosen.

- Perfect Sanitation.

- Adopting SUS316 as material.

- Manufacturing by our subsidiary in China.

Vane Pumps

-

V Series

- Characteristics

- 2 rotor-plates (vanes) slide alternatively and transfer the liquid

- Easy to disassemble and cleaning due to simple structure

- Jacket construction is available

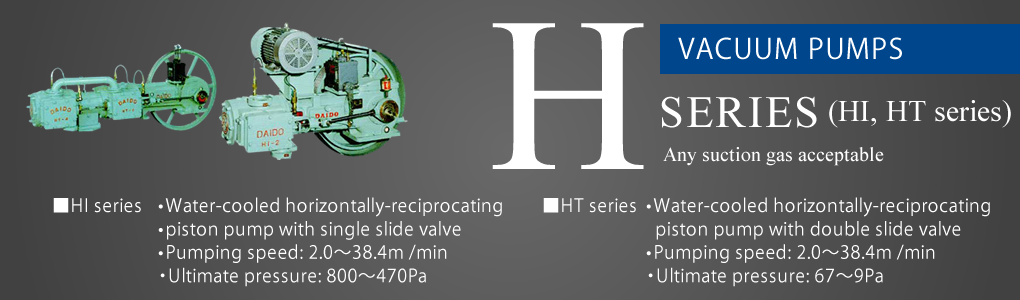

Vacuum Pumps

-

H series

- Characteristics

- Maintenance at site is possible

- Less maintenance time reduced production cost by stopping operation

- Possible to supply peripheral equipment such as silencer, mist separator, etc.